The Lost Art of Hand Sketching and Why We Shouldn't Let It End Up in the Dust Bin of History

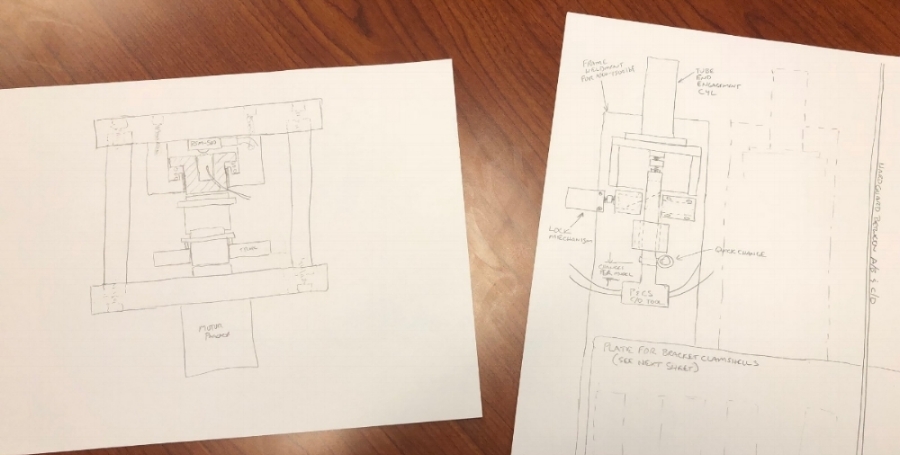

The hand sketch. Seems archaic and overly simplistic in a world of modern CAD that’s now complete with shading and shadows and multiple colors, hyper realistic renderings and even full motion. A throwback to the old days of board design that no longer applies, right? Why get out a pencil and paper and make something that is not to scale and may not be complete when it's just as easy to throw some models together and know for sure? The trend away from sketching actually started back in the 2D CAD times. Designers just inherently started feeling more comfortable in the validity of their concepts when they could see it all fit together to scale. But, even though you can draw/model pretty quickly in both 2D and 3D CAD, the fact is, relatively speaking, they still take more time than a sketch. In my mind, the initial day or two of any design should be about exploring options and ideas. By effectively sketching, you can create 3-4 big picture concepts quickly (should I use a dial? How about a conveyor? Is a robot appropriate?). As in the pics below, you can lay out these multiple system level options in a matter of 10-20 minutes each, start to break down the work content and get a feel for how that translates into station quantity/station content by adding process descriptions, thumbnail cycle time analysis, etc. Once you get more experience in the industry, you can also ballpark cost of each option so you can add that to your analysis of the best solution. By the time you would have modeled what one single station looks like in CAD, you could be making a relatively informed decision on a path forward between several system choices.

Once you have evaluated possible big picture solutions, the next level of sketching is to further develop tooling and station content as shown in the next pic. This has two advantages: one, you can quickly see what motions you may need, what forces would be in play, what sensors and instrumentation is needed and how it may all fit together and within the overall system. Through this discovery phase, cycle times and costs can be refined from your initial system level sketch and that may drive changes in the station or even the selection of an alternate concept; the second advantage is a little more obtuse. With the advent of 3D CAD, many designers have never really had to get proficient at translating 2D into 3D in their heads. Don’t get me wrong, I don’t want to go backwards in technology…..3D CAD is an amazing design and presentation tool and drives better, more elegant solutions because you can see the “final product” as you develop it. But, I do think that the mental gymnastics of looking at something in 2D and having to map out in your mind how those flat rectangles and circles and triangles will interact, clear, and interfere with each other and with the customer product helps to build spatial awareness skills that can take you to the next level of design skill. Being able to close your eyes, lean back in your chair and create a movie of how something will work that doesn’t even exist is a powerful tool and I believe sketching helps develop that ability.

Once upon a time at a place I used to work, we instituted a rule that all stations had to have a concept review within the first few days of design and all concepts had to be brought to the meeting as a hand sketch along with a cycle time analysis. The sketch part of the rule may seem silly, but it had a few advantages. As i said above, even in a simplified form, concepting in CAD requires downloading files, pulling things in from other designs, creating new models, mating things together, etc, and you can burn up 10-20 hours of your budget pretty quickly just getting one idea to a point where it’s representative enough to talk about. In that same time, you could generate sketches for 3-4 ideas, explore the mechanics of those ideas, generate quick cycle time analysis, and even estimate cost, so in the meeting, people have big picture options to debate rather than it just being a critique of whether that bracket should be welded or bent, which is what tends to happen when people perceive the design direction is already picked. Plus, I don’t care how open minded and easygoing you are, there is a pride of ownership that develops when you put time and effort into something. I’ve seen a person who developed a concept using quick sketches wad their sketch up and throw it away without hesitation because someone in the room suggested something better. I’ve also seen people that have spent 20-30 hours “CAD sketching” an idea resist a better solution just because of the investment they’ve already made.

In the end, it’s a valuable tool in the toolbox. As in most engineering endeavors, an iterative approach seems to work best. I’ll make hand sketches of possible layouts and chassis choices to get a feel for how I’d break up the stations, then start sketching tooling, then go back and adjust the layouts and add in cycle times and rough costs, then maybe use AutoCAD to get a feel for whether my concept will be 4’ square or 10' square because that’s a great tool for drawing circles and squares to scale quickly, and then maybe model up some of the trickiest tooling in 3D to make sure my sketched idea will really work. That multi pronged approach lets you jump rapidly back and forth from a few big picture ideas to risky details so you can focus on what’s the most important while still leaving options open and all while limiting hours and calendar time so you can still finish your chosen solution on time and on budget.