Plastics Selection

The Shore Scales

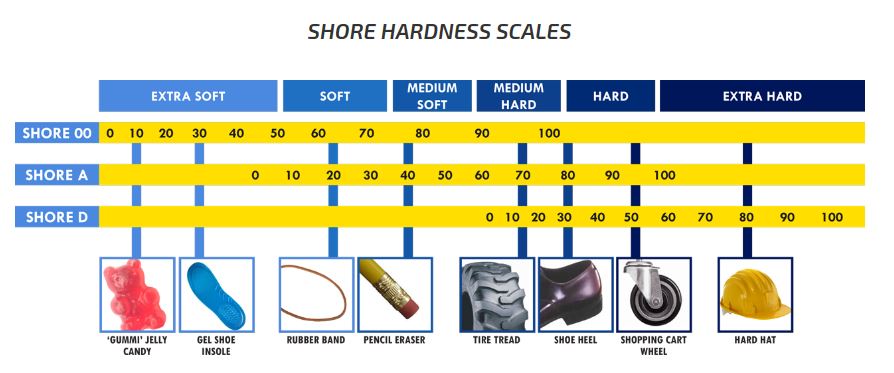

Before we get too far into a discussion of plastics, we should probably review how the hardness of plastic is measured. Typically, it is on a Shore scale. Much like the Rockwell hardness scale (see heat treat post for explanation of that), the Shore scale also has multiple levels to account for the wide range that could be encountered. They are the 00, A, and D scales. Most of the machinable plastics discussed below would be measured on the D scale (see chart), but most of your moldable plastics will likely be in the A scale. I've included a graphic of how those numbers might correlate to everyday materials for your reference below, but I will advise that if you will be using many molds in your designs, you go to your local molder and ask them if they have some samples. I received one once that had a wide range of 1/4" x 1" x 2" pieces on a keychain that had the durometer value molded right into it as a permanent label. It was invaluable when sitting there trying to figure out what the best choice was in a design.

Machinable Plastics

OK, I'm going to admit right up front....I'm not a plastics expert. In fact, after going three Google screens deep into a search, I still can't tell you when to choose nylon over Delrin. But, for what it's worth, here are a few go-to plastics and their uses. I also put together a small table that gives you the basic properties of several well known plastics.

UHMW-PE or UHMW for Short (Ultra High Molecular Weight Polyethylene)

This is an inexpensive and easy to machine plastic that has probably the best coefficient of friction of any of the common materials you'll use and it's also cheap at around $5-6/lb. Unfortunately, it's not very strong, so it's not ideal for nests or structural members. It makes for great wear strips and sliding surfaces if it's backed up by a sturdier structure, and it's ok if it's just for low precision parts whose functionality is not affected by deflection, wear, or dings.

Delrin, Nylon, and Ertalyte

All three of these have similar properties, and can be pretty much interchanged. I think Ertalyte may wear a little better for nests and touch tooling and is used quite a bit for electrical isolation and some for lower temperature thermal isolation/insulation. Delrin tends to be used more for general purpose pieces, It's a little cheaper per pound than Ertalyte, has good mechanical properties, and machines well. I'd say it's the most popular plastic in our industry based on my fairly narrow worldview. Nylon, while pretty much identical to Delrin, doesn't seem to get used as often, but that could just be what I've seen. Your company may have a standard picked from one of these three that makes the choice easy.

Nylatron

Nylatron is a special recipe nylon that is infused with molybdenum disulphide that enhances its mechanical properties and reduces thermal expansion. This makes it an ideal material for homemade bushings and close tolerance wear strips. An additional version, Nylatron GSM Blue, is also infused with oil, which decreases its coefficient of friction and makes it an even better bushing material.

G11 Phenolic (Green Glass)

I have had a lot of success with green glass for nests that are used to isolate hot parts from the rest of the machine. You will see from the chart that its "service temp" (the maximum temperature for continuous use) is only about 100 degrees F higher than the other materials, but the mechanical properties are basically off the charts. You will get excellent wear resistance and its mechanical properties don't degrade as temperature increases. So why not use it for everything? It can be a bit brittle, and it machines off in a dust, so I'm guessing it's not the healthiest thing in the world to work with. I'd probably only use it in high heat/electrical isolation situations.

PEEK

You will see from the chart that PEEK is like a magic plastic. Top numbers in almost every category. And that certainly includes the price at $80/lb, so that's why I would say you probably won't run into a situation where one of the other plastics won't do the job for a lot less money. But it is out there if you ever do need magic.

Table of a Few Common Plastics

I captured a few stats on the plastics I mentioned above to help consolidate all the information in one place. If you google plastics, there are hundreds available, and you can find a lot more specific information on any one of them, but this should get you started.

Poured/Molded Plastics

In addition to the machinable plastics, another nice trick to have in the bag is the ability to pour plastics to a mold for various shapes and functions. This can be especially useful in making specialty seals for leak testing or for creating assembly/test nests when the only way to hold a part is by touching the "Class A" surfaces (those finish surfaces that show on a final product and will be scrapped if that surface is scuffed or scratched during processing).

Seals

For seals, a steel mold is made as the negative of the shape you want, then it's poured and cured. The most common material is Polyurethane (usually just called urethane), but Polyester and Silicon are also used somewhat regularly. There are a host of other specialty materials that can be used for adverse environments, but that's probably for your own research if you're in one of those situations. Seal hardness is selected by balancing the ability to conform to a surface (leaning towards softer) with the seal life (leaning towards harder). I'd say typical hardness for most seals varies from 60-90 Shore (A).

Nests/Fixtures

The overwhelming material of choice for a nest is urethane. Choosing a hardness is a little different for a nest than a seal. In this case, the harder the nest, the easier it is to do something as simple as bolt it down and the longer it will last. But, the harder it is, the more likely it will be to mar the surface of the product, the very thing you're trying to avoid by molding. Too soft, and it could deflect more than you can tolerate in your design or pick up debris that will scratch a part surface. You will likely be in the 40-80 Shore A area for nests. See my post on Poured and Printed Nests for a little more info.